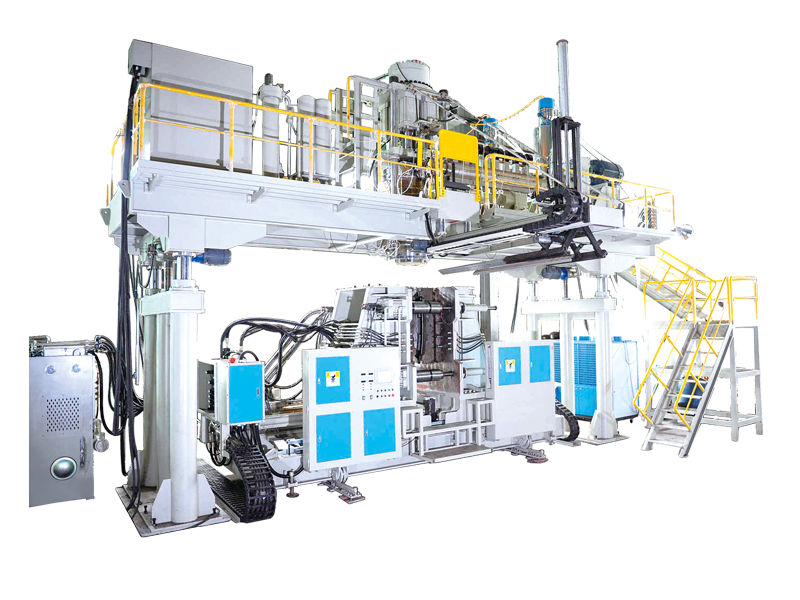

HAM Series

Hydraulic Accumulator Head Multilayer Co-Extrusion Blow Molding Machine

Designed for the container of over-size dimension and ultra capacity.

Multilayer Co-Extrusion accumulator head with particular parison control

for the container up to 3000 L

PWDS-parison wall distribution system is available for a specific product request

Applications:

Large container: Plastic Chemical Drum / IBC Tote / Plastic Water Tank

Outdoor equipments: Traffic barrier / Solar Panel Floater / Plastic Pallet / Kayak

Furniture: Outdoor table & Chair

Automobile: Spare parts / Air duct / Fuel Tank

Multilayer Material: HMWPE / PE / PP / PC / ABS / PETG / NYLON

Features

Check machine specification by choosing container volume

60 Liters

120 Liters

220 Liters

1000 Liters

2000 Liters

Custom made options